A family friend is interested in terra cotta sculpture. Knowing I’ll usually take on any kind of mechanical construction project thrown at me, he asked If I could build him a set of armatures for his sculpting work. These act as a supportive base structure that the clay is layered over top of.

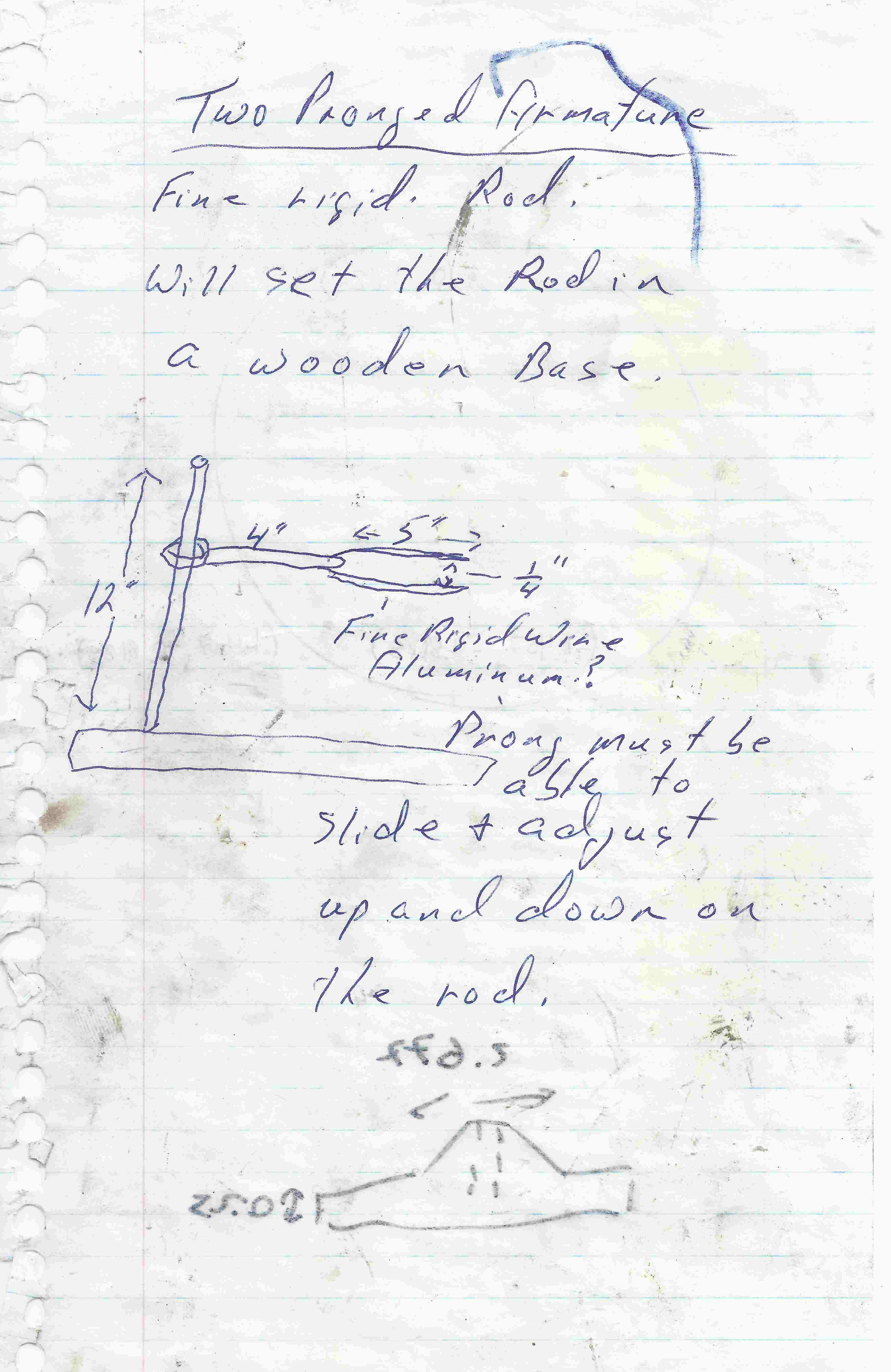

Like a lot of my projects, we start out with a sparse hand sketch from the client.

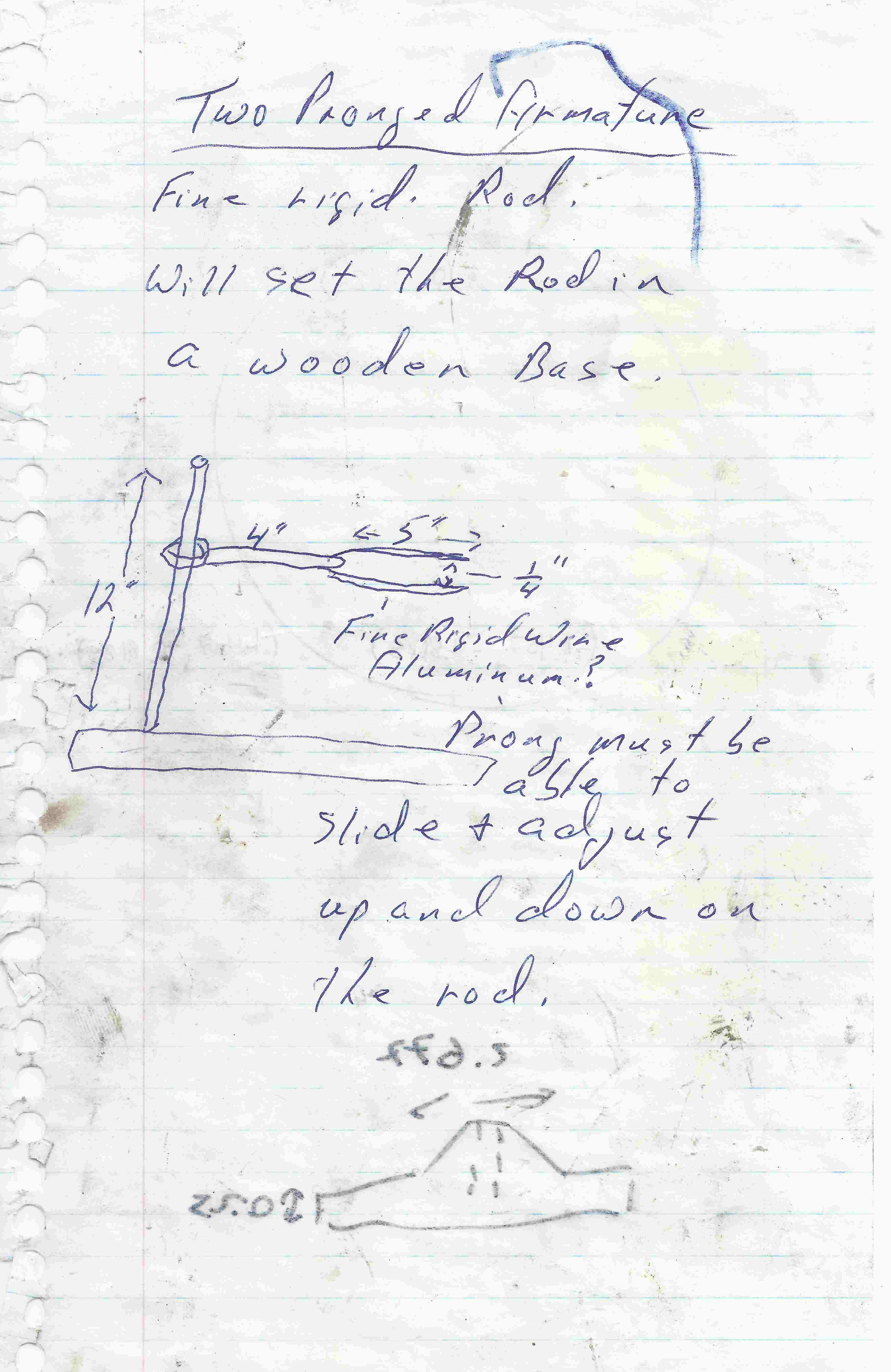

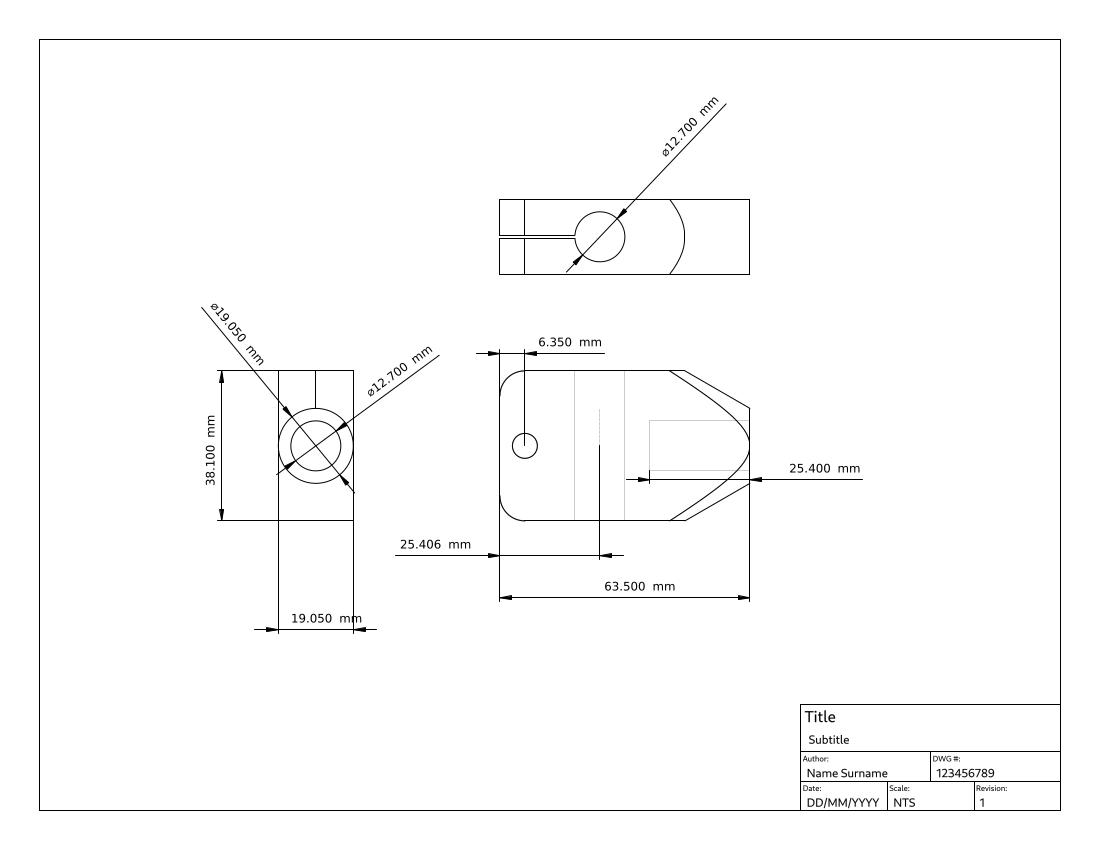

I worked on the design in CAD until I had just enough of a clue to start cutting metal.

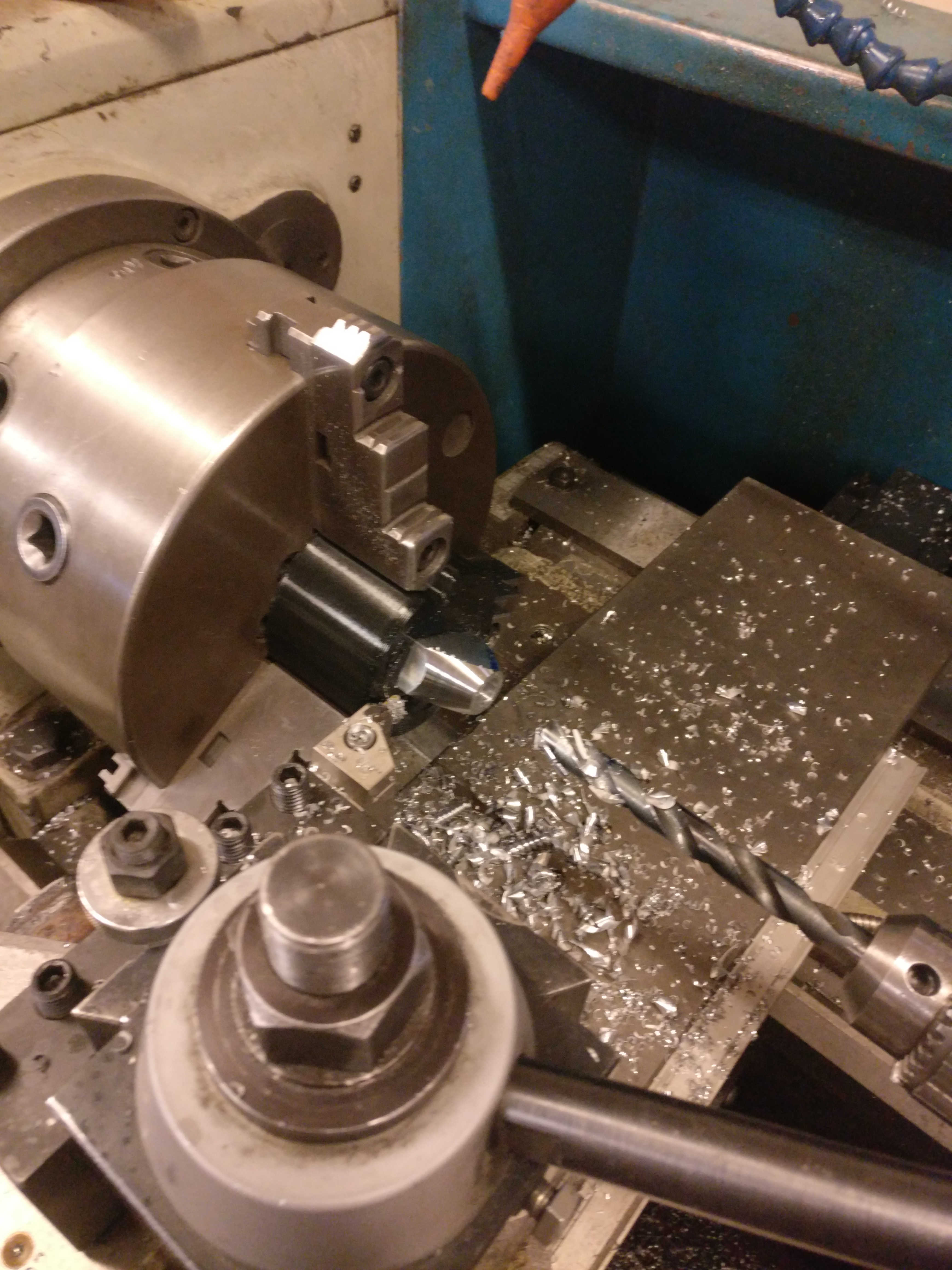

I used 6061 Aluminum for all of the complex machined parts. It’s cheap and cuts well enough if you apply WD-40. The shafts (and some other hardware) are 304 stainless steel. It would have been nice to make the whole thing out of stainless for maximum resistance to wet clay induced corrosion, but that would have significantly increased the cost of materials.

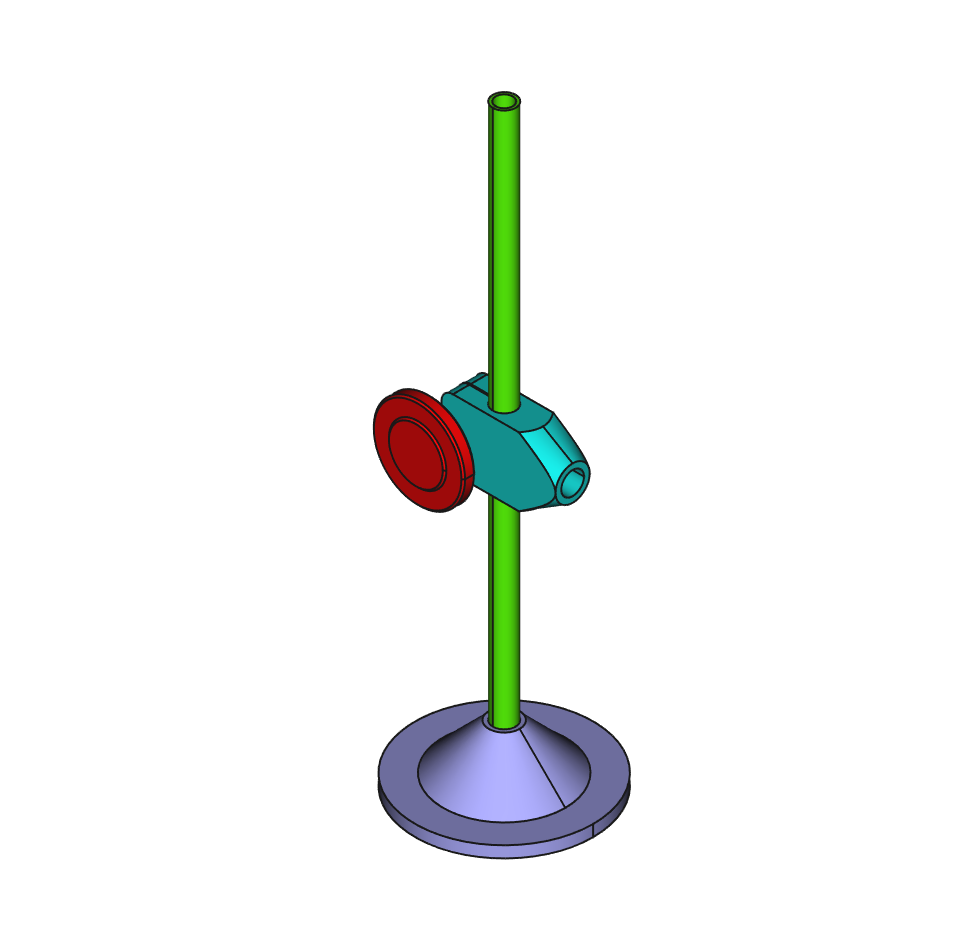

I made drawings for some of the parts, but for a Three-off run like this one, a lot of dimensions get made up on the fly.

One day I’ll own a 4-jaw lathe chuck. Until then, turning tapers on square parts demands creativity. I printed a jig from junk PLA to hold the main body of the armature while I turned off some material:

A 1.2mm nozzle allows for comically fast print speeds, making ridiculous setups like this one almost practical.

One more shot; setting up to drill mounting holes in the base plate:

Overall, I’m happy with how these turned out

Here’s a close up view of the sliding arm. Note the nylon washer under the locking knob. It gives the clamping action a smoother feel.

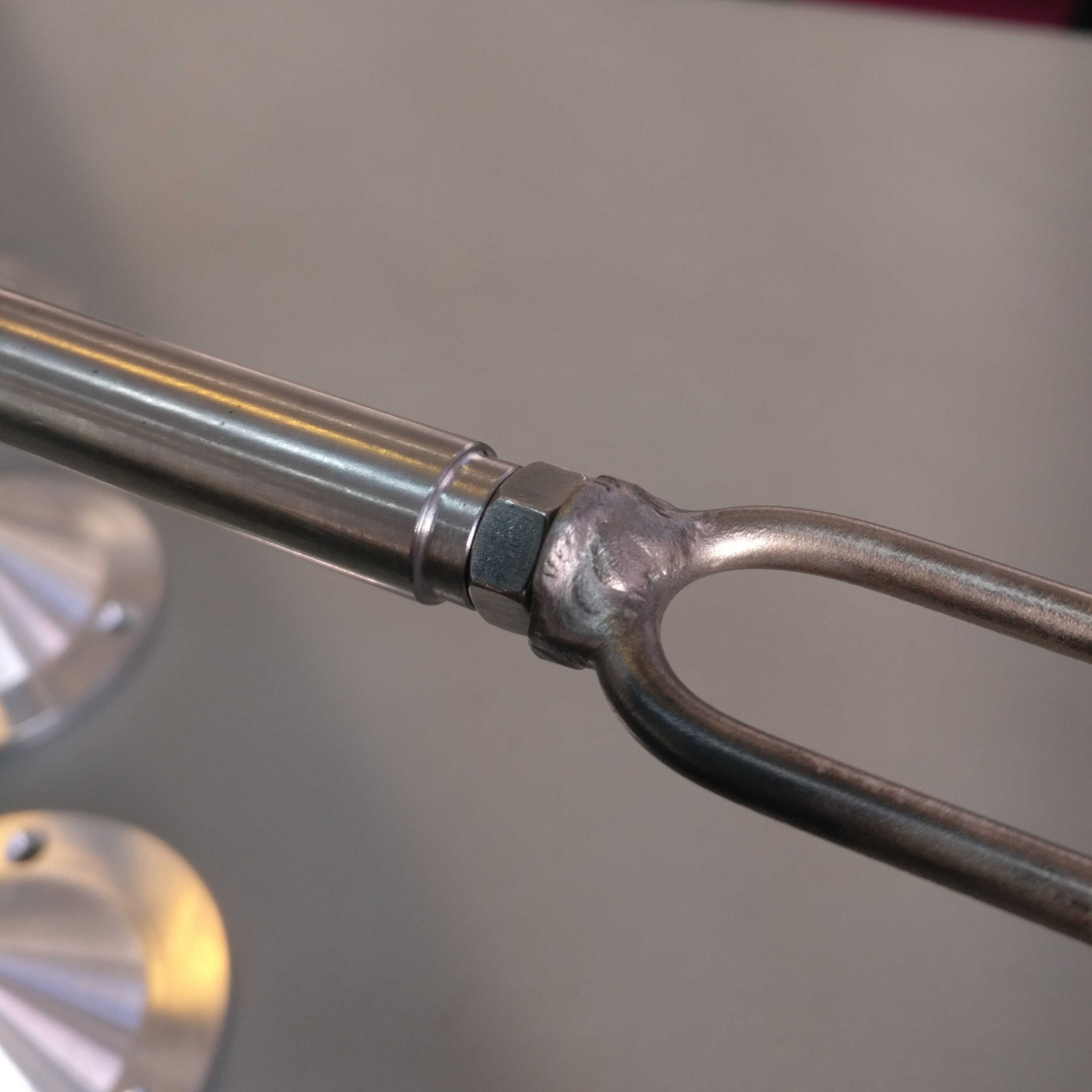

One last image: The front section. The two pronged part, which is what actually holds the clay sculpture, is made of 1/4 inch rod, welded to a pan head screw. I used a simple jam nut system so that different tips can be swapped if necessary.

Thanks for looking, more projects still to come :)