One of my longest term projects to date has been building a custom FDM 3D printer from stock parts and materials. I’m recording some things I learned while building it here, so they can hopefully be useful (or at least interesting) to other people.

I worked through several design iterations across three different CAD software. Coming up with a full model of a full CNC machine turned out to be a workable, if unusual, way to get better at drafting and solid modelling.

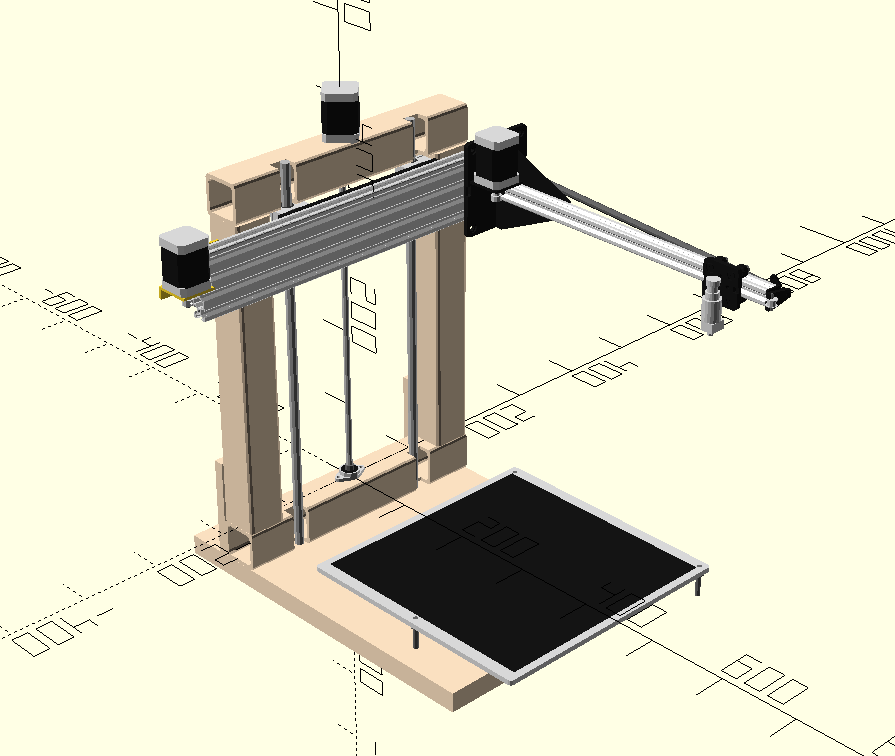

Some early models (OpenSCAD)

The finalized design is a fixed bed machine with a moving gantry and a water-cooled toolhead.

The weakness of this machine’s design is the need for a lightweight toolhead. I ended up custom-machining a water-cooled carriage/cold-side combination part. I’m happy enough with its performance as is, but I still want to keep tinkering with this part of the printer.

Some more images of the printer, from WIP to ‘finished’ state:

The welded steel frame, with the carriage installed:

Laying out and installing the electronics:

Machining the y-axis carriage, one of the machine’s most complicated parts:

Other WIP pics:

The completed printer:

In the off chance you actually want to look at them, I dumped the project files to a git repository Here. No guarantees that any of it will be useful.

Thanks for looking.