I initially designed this as part of an internship at the University of Alberta’s Elko Engineering Garage Makerspace. The goal was to make it easy for makerspace users to get familiar with some of the most popular tools in the space, without needing to design their own project. Overall, this has been really successful. Over 100 project kits have been sold so far. I recieved permission from my employer to make this design open source, so the assembly instructions and design files are available below.

| No. | Item Description | Qty |

|---|---|---|

| 1 | Macro-pad printed circuit board | 1 |

| 2 | Piece of acrylic sheet – 4”x8”x1/16” | 1 |

| 3 | Key switch | 8 |

| 4 | Key cap | 8 |

| 5 | Diode | 10 |

| 6 | Seeed Xiao RP2040 micro-controller with included pin headers | 1 |

| 7 | 7 row 0.1” pitch solder-able pin socket connector | 2 |

| 8 | M3x8mm socket head cap screw | 4 |

| 9 | Brass threaded insert | 4 |

| 10 | 2.5mm hex key | 1 |

The switches in this kit follow a standard form factor for use with keyboards and other input devices. the kit comes with switches that make a noticeable click sound, and require a moderate amount of force to actuate. Many different brands and styles of compatible switches are available, so you can order your own to replace the ones in the kit if you want! (Check out this article for a more in-depth look at keyboard switch types)

Time to complete: 10-30 minutes for print setup, plus about 2 hours of print time.

For this project, we’ll print the housing (or case) out of PLA plastic. The Garage typically stocks 10-15 different colors of this material, so you can pick a style that compliments or contrasts with the other parts of the project. Begin by downloading the 3D model of the case and loading it into your preferred slicing software. (We recommend PrusaSlicer if you’re using a Prusa 3D printer)

3D model: - macropad_case.stl

This isn’t a mechanical part, so the print settings don’t have to be precisely tuned. For your reference, here are some settings that usually work well:

| Parameter | Value |

|---|---|

| Layer Height | 0.2 mm |

| Shell Thickness | 0.8 mm |

| Infill | 20% |

PLA is the most common type of 3D printing filament. It’s typically made in a refining process that starts with fermented corn. It has a low melting point, which makes it easy to print. Mechanical properties vary by brand and print settings, but you usually won’t be able to expect high durability and a long service from this material. That said, it does make usable prototypes quickly and inexpensively. It’s also available in a wide range of nice colors!

Time to complete: 10-45 minutes for setup and cutting.

This design uses an acrylic plate to hold the electrical components inside the case. We’ll cut it out of 1/16” (1.59 mm) cast acrylic sheet. Begin by downloading the following file with the plate cut pattern:

dxf file: - macropad_acrylic_plate.dxf

Open the laser cutter template file (named ’[MM] Blue/Red Laser Template, located on the desktop of the laser cutter workstation) in Adobe Illustrator.

In another Illustrator tab, open the plate file. Make sure to import the file with the ‘Scale by: 100%’ option checked, and set the scale to ‘1 unit(s) = 1 Millimeters’:

Press Ctrl+A to select all of the plate geometry, then press Ctrl+C to copy the plate. Switch back to the laser cutter template tab, then press Ctrl+V to paste the geometry into the template file

Change the line-width of all the visible geometry to 0.001 pt. The laser cutters will cut and engrave geometry in order based on the colors of objects. Change the outer profile to be green (RGB: 0, 255, 0) and make all of the inner features red (RGB: 255, 0, 0). Make sure that your file looks similar to the following screenshot:

To change the print settings in Illustrator, click on print (or press Ctrl+P), then make sure that the ‘ILS’ (red laser cutter) or ‘PLS’ (blue laser cutter) printer type is selected. Then, click on Setup, and then Settings. This will open a menu where you can change the laser parameters. Select the red and green rows of the cut settings table, and change the process type to ‘Vector’. Then, use the material selector to change the cut settings to Cast Acrylic, and the material thickness to 0.07” (1.8 mm). When you are happy with the print settings, click print to send the job to the machine.

Open the UCP laser control software and home the machine if needed. You’ll also need to set up your piece of stock inside the laser cutter. a 100x200mm sheet of acrylic is included with every project kit, so there’s enough space for a second attempt if you get the settings wrong the first time. Use a bit of masking tape along the edges of the sheet to ensure that it doesn’t shift during the cutting operation.

Leave the protective paper or plastic film on during the cutting process. If you peel it off beforehand, the parts will tend to pick up some scratches and burn marks during cutting!

Use the focus view feature to ensure that the part will actually be cut from the right part of the sheet. When you’re happy, hit run, and you should get a finished part in only a minute or two.

Acrylic is a good first choice for plastic parts. It’s rigid, inexpensive, and available in all common sizes of sheets, rods, and tubes. you can laser-cut it, as well as drill and saw it with normal woodworking tools. Acrylic can be bonded with Cyanoacrylate glue (A.K.A. super glue). If you plan on purchasing some of this stuff for your own projects, make sure to get cast acrylic, rather than extruded acrylic. Cast material is much easier to work with, especially when using a laser cutter.

Time to complete: 20 minutes to 1 hour, depending on your soldering experience.

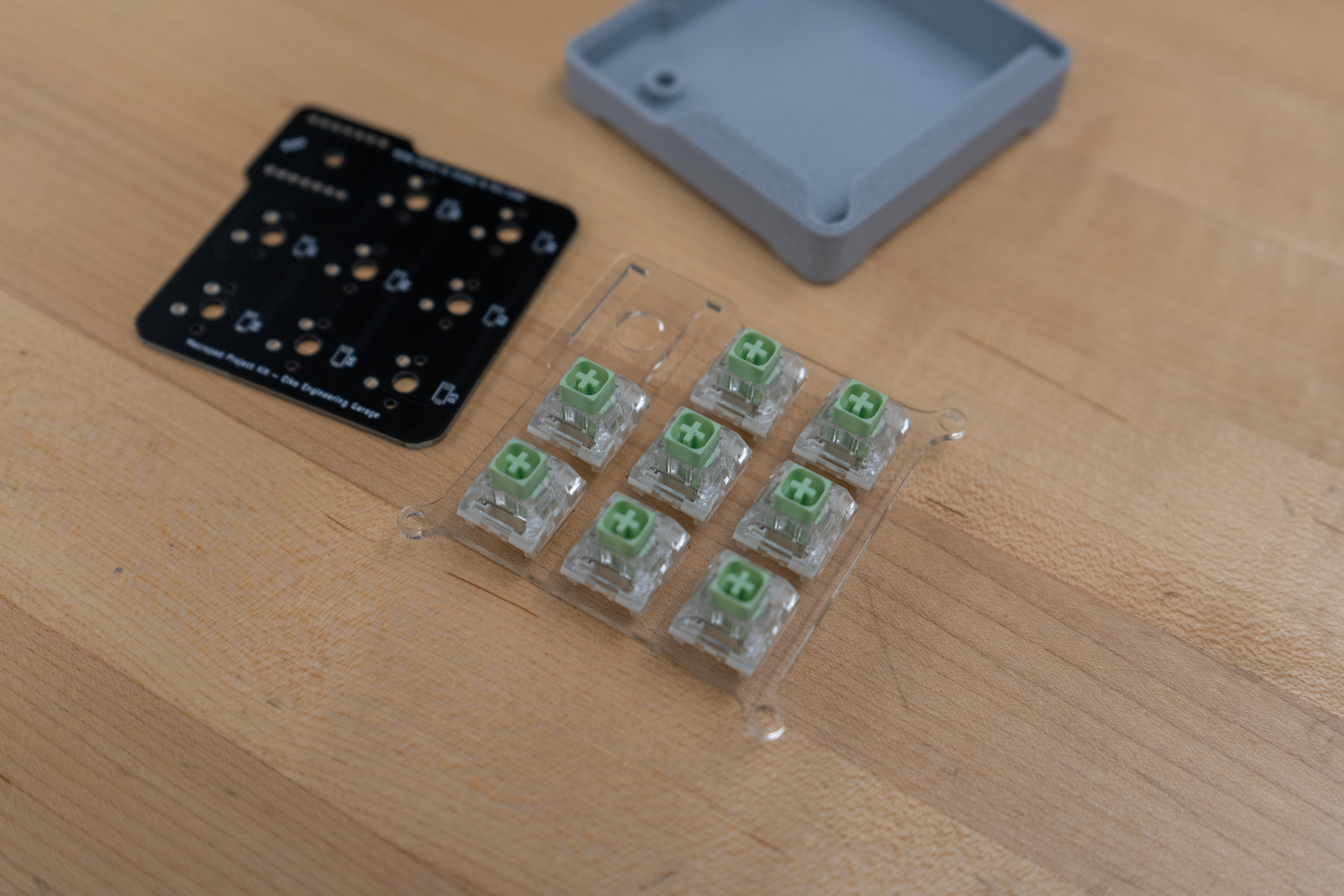

At this point, you should have a case and an acrylic plate. Let’s get it all assembled! First, press the switches through their matching holes in the acrylic plate. Make sure to remove the protective film from the acrylic before adding the switches. The holes are square, so you’ll need to get each switch in the correct orientation.

Once the switches are firmly seated in their correct locations, firmly press the PCB onto the plate-switch assembly. It should take a bit of force, since the pins molded into the switch housings are a press fit with the holes in the PCB. Make sure that all of the switches are fully seated and sitting correctly on the top surface of the PCB.

With the switches, plate, and PCB squashed into one piece, it’s now time to begin soldering. You’ll most likely want to install the smallest, pointiest soldering tip available. Turn on the soldering iron and wait for it to heat up completely. You’ll know it’s ready to go when the green LED on the housing starts blinking rapidly. The temperature dial on the soldering iron should be set to about 700 degrees Fahrenheit. Solder each of the pins on the key-switches. (there are 8x2 = 16 of them). You should aim to create a nice and smooth conical joint with not-too-much and not-too-little solder. Take your time, and if you make a joint you don’t like, use the solder wicking braid to clean it up and try again.

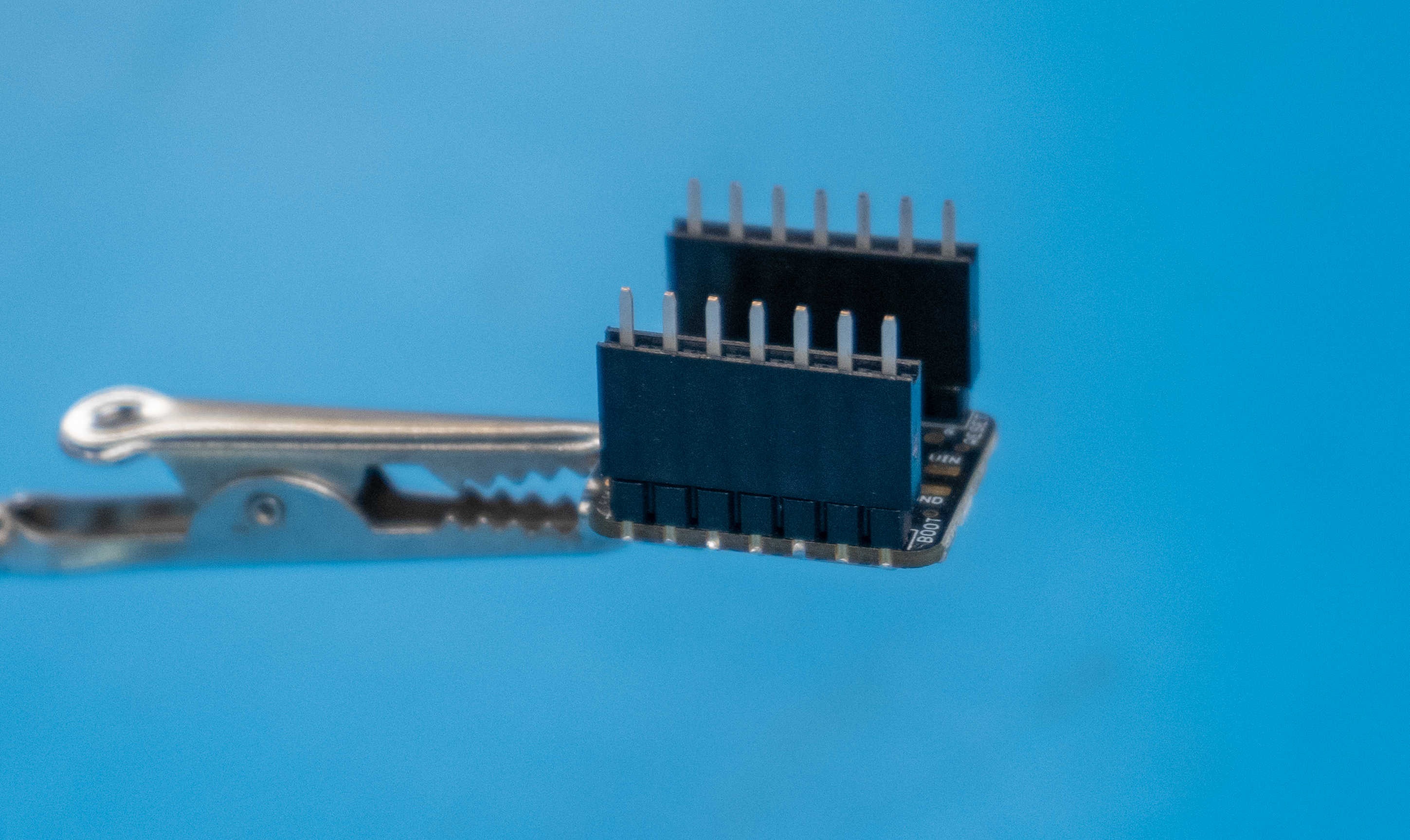

Next, you’ll need to prep the micro-controller (MCU) for assembly. Take it out of it’s package and push the pin headers into the two rows of holes in the board. The shorter leads on the pin headers go up into the micro-controller, and the longer sets of leads stick down to connect to the other parts of the assembly. Solder each of the leads on the pin headers to the MCU. We aren’t connecting most of the pins to anything electrically, but soldering them all adds a bit of mechanical strength.

Next, push the pin header sockets into the exposed header side on the MCU.

Slot the entire MCU sub-assembly through the acrylic plate and into the PCB (facing upwards, like the switches) and solder the sockets of the MCU and the key switches to the main PCB.

Don’t solder the micro-controller directly to the main PCB. You won’t be able to access one of the mounting holes needed to hold the PCB assembly into the case!

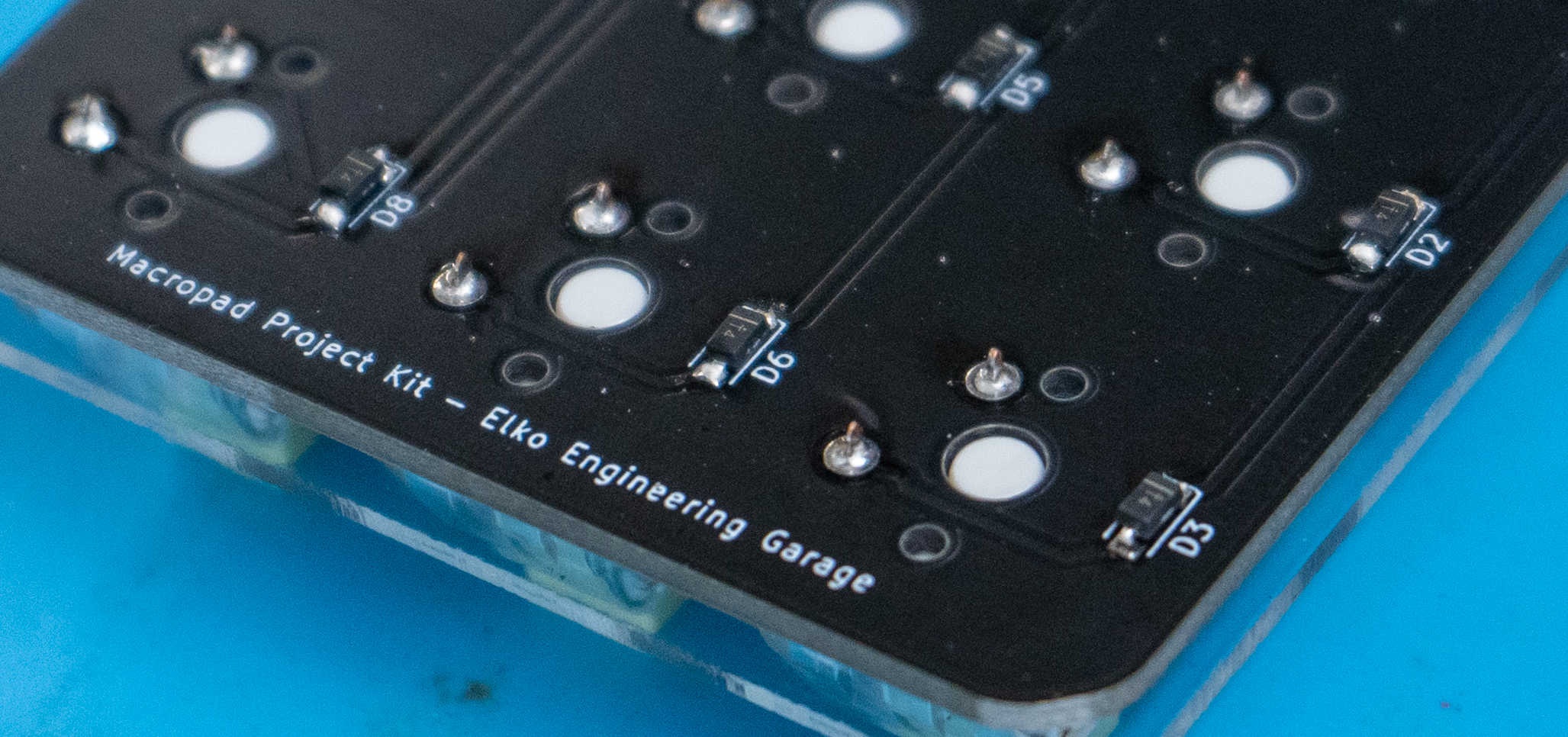

The final components we need to solder are the diodes. They are supplied to us in a surface-mount-technology (SMT) form factor. This style of component is extremely common in newish electronics, because they are smaller and cheaper. For assembly by hand, however, they are slightly more challenging to solder. Note that the diodes also have a polarity, so you’ll need to orient the small white mark on each component to the side indicated by the text on the PCB. Soldering up all 8 diodes will be a bit of a challenge, but it’s a great way to build your soldering skills. A few extra diodes are included in the kit in case you misplace one. Our suggested technique for soldering SMT components is as follows:

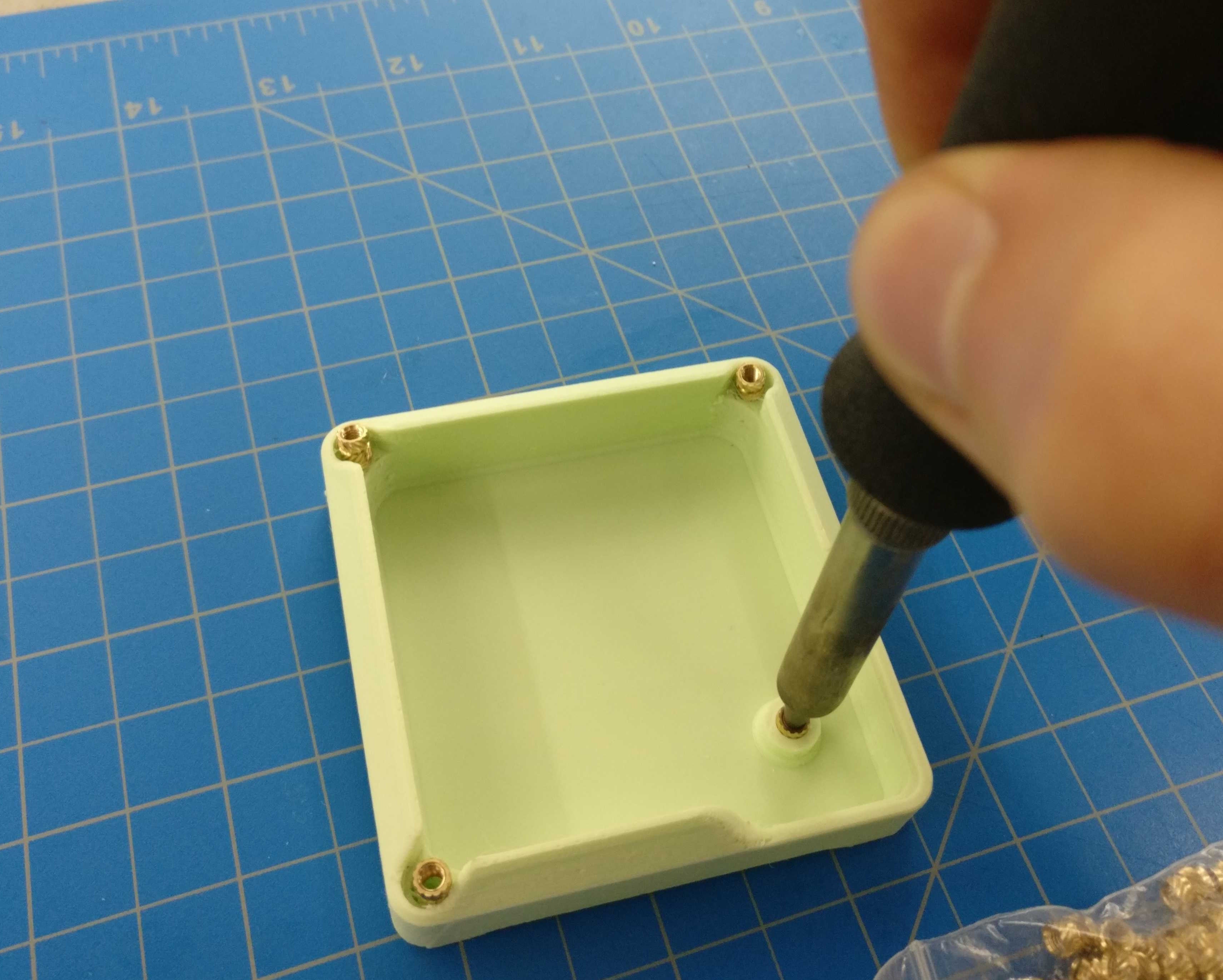

While you are at the soldering iron station, use the iron tip to press the heat-set inserts into the 3D-printed plastic case. All of the brass inserts should be pushed in from the top side, and should be inserted until they are just flush with the surface of the 3D print. Do this step carefully, making sure not to melt too much of the plastic.

You can now use the M3 screws included in the project kit to fasten the switch assembly to the case. Note that you’ll need to pull the micro-controller assembly off of the pin sockets to access the screw underneath. You’ll then be ready to move on to the next step!

Time to complete: 15-30 minutes.

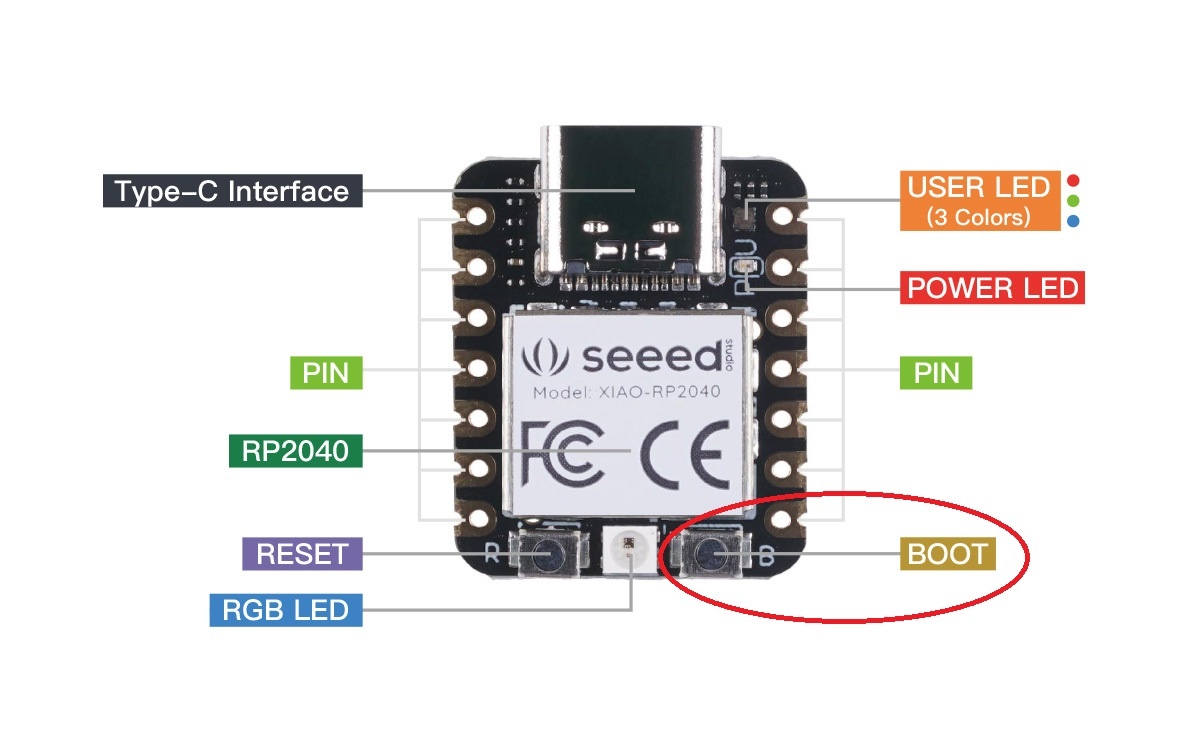

Connect a USB type-C cable to the MCU. Then, press and hold the small ‘boot’ button on the board, while simultaneously plugging in the other end of the USB cable to your computer.

Go to your File Explorer, and you should be able to access the internal storage of the MCU as if it were a USB thumb-drive. You should see a folder called ‘RPI-RP2’ or something similar. It should contain two files, called “INDEX” and “INFO_UF2”.

Delete the existing files, and copy the following .uf2 firmware file to the MCU storage.

Firmware file: - adafruit-circuitpython-seeeduino_xiao_rp2040-en_US-8.1.0.uf2

The micro-controller should immediately recognize the new firmware, and automatically reboot itself. It will now appear in your file explorer as a device called ‘CIRCUITPY’.

Delete the file ‘code.py’ file and the ‘lib’ folder. Copy the contents of the following zip file (a new ‘code.py’ and ‘lib’ folder) into the MCU storage.

Make sure to extract the files before you copy them. Just putting the zipped folder into the micro-controller storage won’t do anything useful!

CircuitPython code: - circuitpython_code.zip

Next, unplug the macro-pad from your PC or laptop, then plug it back in. The on-board LED should flash yellow four times. If it flashes red, some kind of error occurred. In that case, try re-copying the code files onto the board.

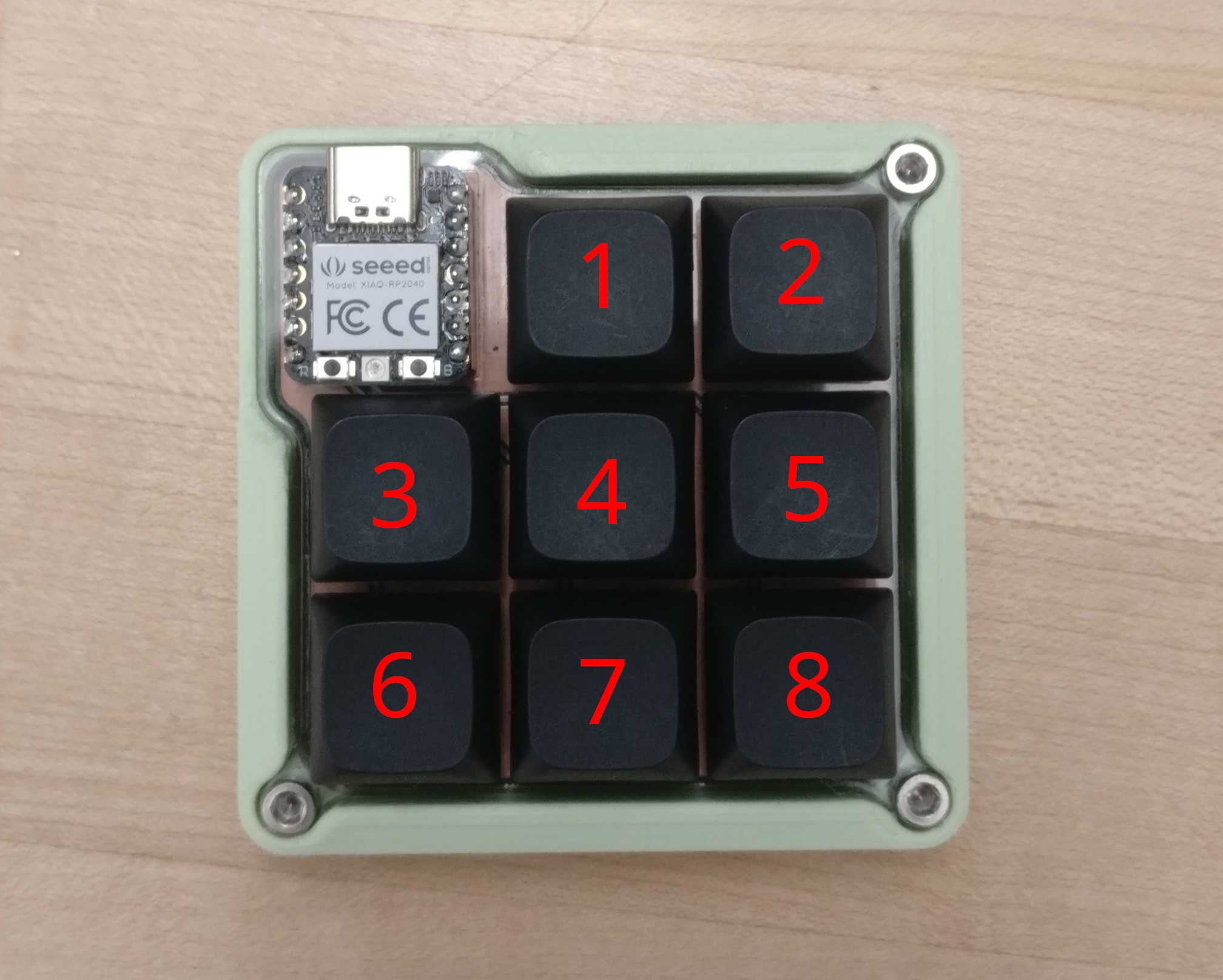

You can now test out the keypad! If any of the keys don’t work, check your soldering for missed or broken connections. You can also edit the pressed key that the macro-pad will send by changing the ‘keypress_map’ variable in the ‘code.py’ file using a text editor. The key numbering is as follows:

# refer to the documentation for a list of available keycodes:

# https://docs.circuitpython.org/projects/hid/en/latest/api.html#adafruit_hid.keycode.Keycode

keypress_map = {

1: lambda: layout.write("Hello, World!"), # type a sequence of letters

2: lambda: kbd.send(Keycode.A), # type a single character

3: lambda: kbd.send(Keycode.LEFT_CONTROL, Keycode.C), # copy and paste

4: lambda: kbd.send(Keycode.LEFT_CONTROL, Keycode.V), # by sending multiple keycodes

5: lambda: kbd.send(Keycode.D), # change these to suit your needs!

6: lambda: kbd.send(Keycode.E),

7: lambda: kbd.send(Keycode.F),

8: lambda: kbd.send(Keycode.G),

}You should now have a finished macro-pad. You can change the key configurations to make it easier to use your favorite CAD software, or add some hotkeys for gaming and productivity. If you want to make your macro-pad even cooler, check out the appendix for some ideas on using different materials and manufacturing processes for the case and other parts. Thanks for completing this project!

Some of the parts of the macro-pad can be constructed in different ways than the ones described in these instructions:

Here are the solid models and PCB design files - They may be useful to you if you attempt to make modifications to this project: